ABOUT

ABOUT

Definition

Drift ... The unwanted and potentially harmful placement of a portion of your spray job off target. A result of small droplets that move with winds or inversions. You know the risks associated with drift; from strained customer relations to liability for damages.

Droplet Size ... The heart of solving these concerns and risks. Though equipment, nozzles, and total systems are designed with an ideal droplet size and performance in mind, they still produce a worrisome amount of fines. Regardless of your care and skill in application, the presence of fine droplets may reduce your spray and operation efficiency.

Deposit Pattern . . . Consists of amount deposited and uniformity of coverage. Droplet sizes must be balanced for best results with least risks: smaller droplets for coverage; larger droplets for volume deposited. When the balance of your spray application shifts to droplets smaller than ideal, you get coverage but are subject to drift and evaporation. When droplets shift to the large side of the balance, you gain on drift, evaporation, and deposition, but lose on coverage and, possibly, product performance.

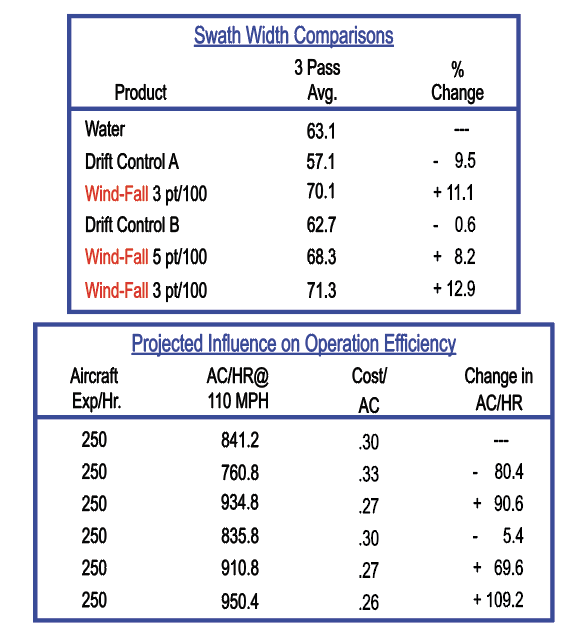

Swath Width . . . Represents the area consistently covered with uniform deposition and coverage each pass. The wider your effective swath width, the more work you can accomplish in a day and the lower your cost of operation will be. If you cannot depend on consistent width, coverage, and deposition you may encounter skips that have to be retreated, poor product performance and operation costs higher than necessary.

Solution

Drift ... Risks increase with small droplets, especially those under 200 microns.

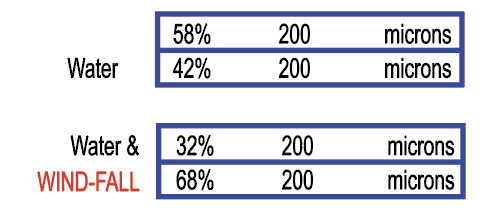

Droplet Size ... Can be manipulated by WIND-FALL to reduce the volume of sprays made up by droplets less than 200 microns in diameter. Laser analysis of on aircraft spray pattern documents the influence of WIND-FALL on droplet size. WIND-FALL effectively shifted 26% of the volume and risks of smaller droplets to larger, safer droplets.

Deposition Pattern ... Shifting the volume of smaller droplets to larger droplets increases the number and volume of spray droplets that will deposit on and cover a target. In aerial applications over deposition cards with a dye added to the water, WIND-FALL exhibited superior deposition and uniformity of coverage.

Swath Width ... Reduced drift risk, increased deposition, and improved coverage are no bargain if swath width is penalized, thus driving up the cost of operation. WIND-FALL has actually increased effective swath width while reducing the risks of other concerns. While these increases can reduce operation costs by an equivalent amount, wind-fall also allows for more work to be completed in the same amount of time.

This clear nonionic liquid is an additive for use with most agricultural chemicals. WIND-FALL is concentrated, easy to blend, non-flammable, and safe to handle. In aerial spray tests the following results were confirmed:

( 1) Reduction of spattering and misting of aqueous solutions

(2) No crop bum.

(3) Spray drift reduced (reduction of vortex effect caused by aircraft on spray pattern).

(4) Evaporation of chemicals decreased 30-40%.

(5) Valves and spray heads lubricated.

(6) Immediate solubility with water based chemical products.

(7) Stability in products up to 1 year.

(8) Increased adherence to plant and leaf surface

Label Information

WIND-FALL is packaged in recycled 2.5 gallon white translucent gauged jugs and in 250 gallon Recycled black or grey U.V. Resistant totes. The recommended mix rate for WIND-FALL Is 1 quart to one hundred gallons of spray product. Every sprayer uses different equipment, different chemicals and sprays under different conditions. Start with 1 quart per hundred and adjust the application as needed to reach desired efficacy. Doubling up on WIND-FALL on windy applications will improve efficacy and reducing the amount of product may prove effective when filtered water or less wind is observed. One or two cycles through tank is sufficient for complete blend. WIND-FALL has a guaranteed 2 year shelf life when stored outdoors in our U.V. protected tote/shuttle or indoors in our original containers!

Caution: Care should be exercised when mixing wettable powders and WIND-FALL. Mix a small amount (1 quart) water and WIND-FALL first. Then add wettable powder to check for compatibility.

If you are unfamiliar with the compatibility of other chemicals you are mixing with WIND-FALL, mix 1 quart water and chemical first and add WIND-FALL to pretest for compatibility.

NOTICE: WIND-FALL Distributors Warrants that the product conforms to its chemical description and is reasonably fit for the purposes stated on the label when used in accordance with directions under normal conditions of use, but neither this warranty nor any other warranty of merchantability or fitness for a particular purpose, express or implied, extends to the use of this product contrary to label instructions, or under abnormal conditions, or under conditions not reasonably foreseeable to WIND-FALL Distributors and buyer assumes the risk of any such use. WIND-FALL Distributors shall not be responsible for incidental or consequential damages, if any, resulting from a breach of warranty.

WIND-FALL ® is a registered trademark.