TESTS

SPRAY PATTERN TEST

Spray Pattern Test Analysis

DENNIS GARDISSER

153 92nd W, Lonoke AR 72086

dgardisser@wrkofar.com

(501) 676-1762

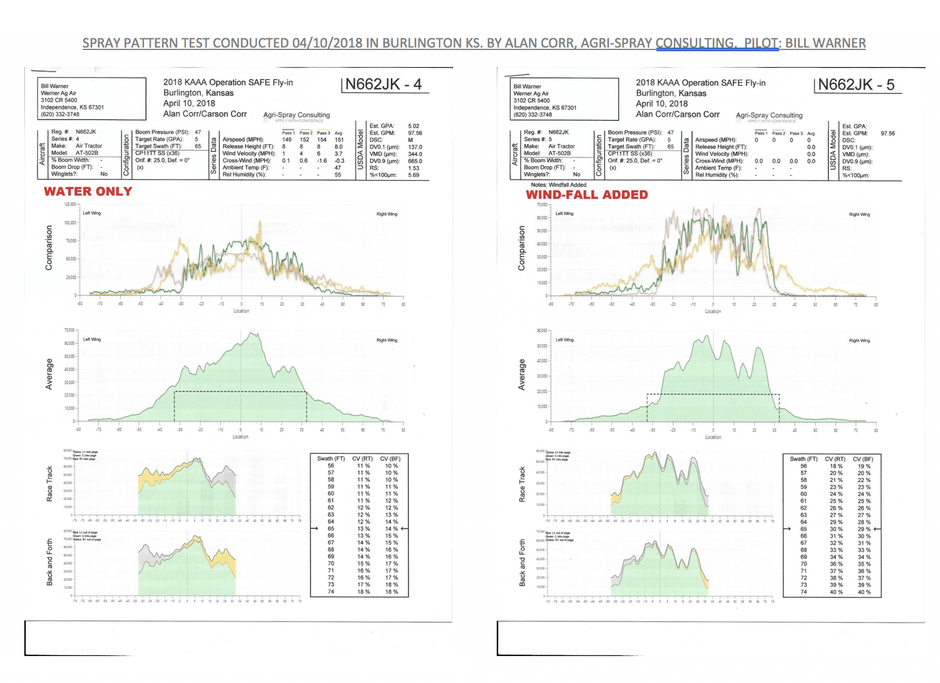

Spray Pattern Test, WIND-FALL Drift Control, Surfactant, Evaporation Reduction

Winnie TX - Twin County Air Ag Inc. - spray deposition evaluations - March 19, 2018:

Air Tractor 602, 143 mph, combination of CP11TT/4015 & 4025 nozzles/ 0 degree deflection, 14’ application height, 5 GPA setup

Materials tested:

1. Water with Rhodamine WT dye at 50ml/100 gallon of solution.

2. Water with WindFall at 1 qt/100 gallon and Rhodamine WT dye at 50ml/100 gallon of solution.

DropletScan values in same order:

1. WATER 2. WIND-FALL

VMD 268 331

Vd.1 168 197

Vd.9 403 458

Est GPA 1.8 2.2

%AC 5.4 6.3

Observations:

1. Addition of Wind-Fall increased all the values evaluated:

VMD 93.5% increase in droplet volume

Vd.1 61% increase in droplet volume - this is the smallest droplet values - so any increases in droplet size reduce drift and evaporation impact potentials.

Vd.9 47% increase in droplet volume - but… should not be enough to adversely affect potential efficacy.

GPA 20% increase in estimated deposition

%AC ~ 16% in collector surface coverage

This is data with a single evaluation where weather variables may have significant impacts - so results should be taken with this snapshot in consideration. (Ed. 3 passes with water, immediately followed by 3 passes with WIND-FALL. All passes conducted 03/19/18, from 1805 hours to 1823 hours = 18 minutes)

Overall - in this evaluation, the addition of Wind-Fall in the solution appears to have a significant positive impact on the key droplet spectrum properties that influence potential deposition and environmental stewardship.

153 92nd W, Lonoke AR 72086

dgardisser@wrkofar.com

(501) 676-1762

Spray Pattern Test, WIND-FALL Drift Control, Surfactant, Evaporation Reduction

Winnie TX - Twin County Air Ag Inc. - spray deposition evaluations - March 19, 2018:

Air Tractor 602, 143 mph, combination of CP11TT/4015 & 4025 nozzles/ 0 degree deflection, 14’ application height, 5 GPA setup

Materials tested:

1. Water with Rhodamine WT dye at 50ml/100 gallon of solution.

2. Water with WindFall at 1 qt/100 gallon and Rhodamine WT dye at 50ml/100 gallon of solution.

DropletScan values in same order:

1. WATER 2. WIND-FALL

VMD 268 331

Vd.1 168 197

Vd.9 403 458

Est GPA 1.8 2.2

%AC 5.4 6.3

Observations:

1. Addition of Wind-Fall increased all the values evaluated:

VMD 93.5% increase in droplet volume

Vd.1 61% increase in droplet volume - this is the smallest droplet values - so any increases in droplet size reduce drift and evaporation impact potentials.

Vd.9 47% increase in droplet volume - but… should not be enough to adversely affect potential efficacy.

GPA 20% increase in estimated deposition

%AC ~ 16% in collector surface coverage

This is data with a single evaluation where weather variables may have significant impacts - so results should be taken with this snapshot in consideration. (Ed. 3 passes with water, immediately followed by 3 passes with WIND-FALL. All passes conducted 03/19/18, from 1805 hours to 1823 hours = 18 minutes)

Overall - in this evaluation, the addition of Wind-Fall in the solution appears to have a significant positive impact on the key droplet spectrum properties that influence potential deposition and environmental stewardship.

DENNIS GARDISSER

153 92nd W, Lonoke AR 72086

dgardisser@wrkofar.com

(501) 676-1762

Spray Pattern Test, WIND-FALL Drift Control, Surfactant, Evaporation Reduction

Winnie TX - Twin County Air Ag Inc. - spray deposition evaluations - March 19, 2018:

Air Tractor 602, 143 mph, combination of CP11TT/4015 & 4025 nozzles/ 0 degree deflection, 14’ application height, 5 GPA setup

Materials tested:

1. Water with Rhodamine WT dye at 50ml/100 gallon of solution.

2. Water with WindFall at 1 qt/100 gallon and Rhodamine WT dye at 50ml/100 gallon of solution.

DropletScan values in same order:

1. WATER 2. WIND-FALL

VMD 268 331

Vd.1 168 197

Vd.9 403 458

Est GPA 1.8 2.2

%AC 5.4 6.3

Observations:

1. Addition of Wind-Fall increased all the values evaluated:

VMD 93.5% increase in droplet volume

Vd.1 61% increase in droplet volume - this is the smallest droplet values - so any increases in droplet size reduce drift and evaporation impact potentials.

Vd.9 47% increase in droplet volume - but… should not be enough to adversely affect potential efficacy.

GPA 20% increase in estimated deposition

%AC ~ 16% in collector surface coverage

This is data with a single evaluation where weather variables may have significant impacts - so results should be taken with this snapshot in consideration. (Ed. 3 passes with water, immediately followed by 3 passes with WIND-FALL. All passes conducted 03/19/18, from 1805 hours to 1823 hours = 18 minutes)

Overall - in this evaluation, the addition of Wind-Fall in the solution appears to have a significant positive impact on the key droplet spectrum properties that influence potential deposition and environmental stewardship.

153 92nd W, Lonoke AR 72086

dgardisser@wrkofar.com

(501) 676-1762

Spray Pattern Test, WIND-FALL Drift Control, Surfactant, Evaporation Reduction

Winnie TX - Twin County Air Ag Inc. - spray deposition evaluations - March 19, 2018:

Air Tractor 602, 143 mph, combination of CP11TT/4015 & 4025 nozzles/ 0 degree deflection, 14’ application height, 5 GPA setup

Materials tested:

1. Water with Rhodamine WT dye at 50ml/100 gallon of solution.

2. Water with WindFall at 1 qt/100 gallon and Rhodamine WT dye at 50ml/100 gallon of solution.

DropletScan values in same order:

1. WATER 2. WIND-FALL

VMD 268 331

Vd.1 168 197

Vd.9 403 458

Est GPA 1.8 2.2

%AC 5.4 6.3

Observations:

1. Addition of Wind-Fall increased all the values evaluated:

VMD 93.5% increase in droplet volume

Vd.1 61% increase in droplet volume - this is the smallest droplet values - so any increases in droplet size reduce drift and evaporation impact potentials.

Vd.9 47% increase in droplet volume - but… should not be enough to adversely affect potential efficacy.

GPA 20% increase in estimated deposition

%AC ~ 16% in collector surface coverage

This is data with a single evaluation where weather variables may have significant impacts - so results should be taken with this snapshot in consideration. (Ed. 3 passes with water, immediately followed by 3 passes with WIND-FALL. All passes conducted 03/19/18, from 1805 hours to 1823 hours = 18 minutes)

Overall - in this evaluation, the addition of Wind-Fall in the solution appears to have a significant positive impact on the key droplet spectrum properties that influence potential deposition and environmental stewardship.

ASTM Report Analysis

On April 1, 2018 at 9:05 AM DENNIS GARDISSER <dgardisser@wrkofar.com> wrote:

I reviewed the “Psysico-Chemical Properties, In-flight evaporation and Spread of Spray Droplets Containing Pesticide Adjuvants” as you requested. I will summarize my thoughts in the following bulleted format:

1. This appears to be a very good study done by some very knowledgeable scientists. Credibility wise - it should be very good. Many times consumers are leery of company generated data.

2. Obviously Windfall faired very well in the tests for both coverage and evaporation reduction. These are both excellent qualities for application efficacy and environmental stewardship.

3. The results of this study should be a great tool for prediction of spray application performance for ground based applications.

4. The study is quite limited on droplet size(s) reviewed. the upper limit was 200 microns - which is the size that most applicators try to stay above for evaporation reduction and drift potential. Small droplets have a much greater surface area per unit volume than their larger counterparts.

5. Most of the data in this report should not be used to imply performance in any aspect of aerial applications. A wind tunnel study similar to this to determine what happens to droplets exposed to high shear would be needed for evaluation from aircraft applications.

6. The reduction in evaporation potential should be a benefit to any application and help avoid increasing drift potential of smaller droplet spectrums due to inflight evaporation.

7. The spread factor for Windfall on WSP is very similar to water - which would allow comparisons on depositions with both on WSP at Operation SAFE clinics to have excellent correlations. Since these are close - DropletScan readings from water vs Windfall taken under actual aircraft application simulations should provide an excellent way to demonstrate application efficiencies.

DENNIS GARDISSER

153 92nd W, Lonoke AR 72086

dgardisser@wrkofar.com

(501) 676-1762

"Click to View ASTM Study on Ground Spray Evaporation and Spread with various Adjuvants"

I reviewed the “Psysico-Chemical Properties, In-flight evaporation and Spread of Spray Droplets Containing Pesticide Adjuvants” as you requested. I will summarize my thoughts in the following bulleted format:

1. This appears to be a very good study done by some very knowledgeable scientists. Credibility wise - it should be very good. Many times consumers are leery of company generated data.

2. Obviously Windfall faired very well in the tests for both coverage and evaporation reduction. These are both excellent qualities for application efficacy and environmental stewardship.

3. The results of this study should be a great tool for prediction of spray application performance for ground based applications.

4. The study is quite limited on droplet size(s) reviewed. the upper limit was 200 microns - which is the size that most applicators try to stay above for evaporation reduction and drift potential. Small droplets have a much greater surface area per unit volume than their larger counterparts.

5. Most of the data in this report should not be used to imply performance in any aspect of aerial applications. A wind tunnel study similar to this to determine what happens to droplets exposed to high shear would be needed for evaluation from aircraft applications.

6. The reduction in evaporation potential should be a benefit to any application and help avoid increasing drift potential of smaller droplet spectrums due to inflight evaporation.

7. The spread factor for Windfall on WSP is very similar to water - which would allow comparisons on depositions with both on WSP at Operation SAFE clinics to have excellent correlations. Since these are close - DropletScan readings from water vs Windfall taken under actual aircraft application simulations should provide an excellent way to demonstrate application efficiencies.

DENNIS GARDISSER

153 92nd W, Lonoke AR 72086

dgardisser@wrkofar.com

(501) 676-1762